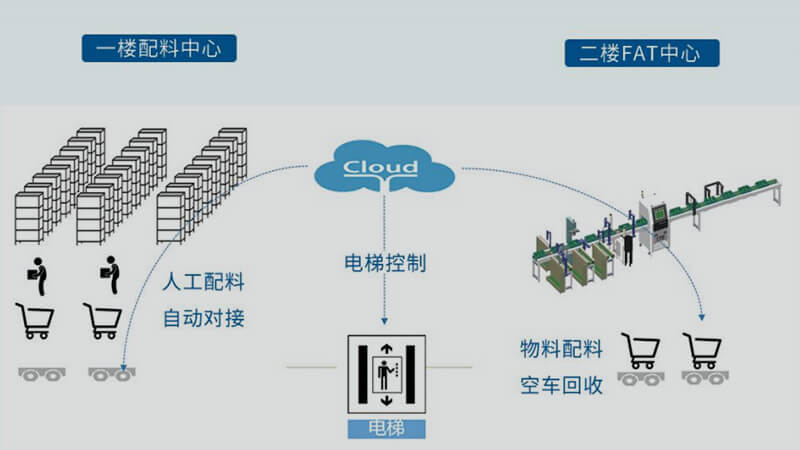

Automatic operation

Automatic operation of cargo handling and elevator control.

Triple safety

Triple safety intelligent obstacle avoidance system to ensure the safe operation of the system.

Strong expansibility

Windows operating system, simple operation and strong scalability.

Unified scheduling

Unified dispatching platform, intelligent central centralized control system.

Remote operation

The wireless communication system of special lifting and handling robot is convenient for remote operation and monitoring.