October 27-28, the 2021(2nd) Annual Conference on high-tech mobile robots, hosted by the Institute of high-tech Mobile Robots and high-tech robot industry (GGII) , was held at the zhuomeya Himalayas Hotel in Shanghai, zheng Chao, vice-president of blue chip technology, gave a speech entitled “Deep Vision”in the special session on digital intelligence ecology.

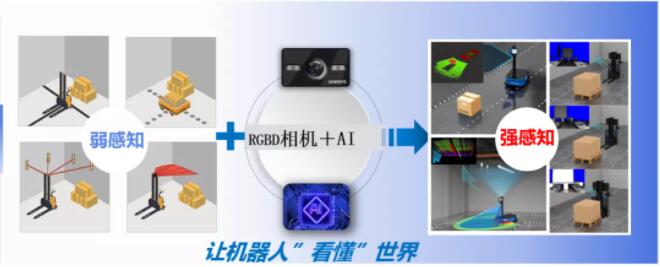

“At present, the mobile robots, including a, are like a blind person,”Zheng said. “The perception of the environment requires constantly ‘touching’the surrounding environment, and then moving forward step by step. The perception of the environment depends entirely on the range of his ‘touching’. The current mainstream AIS scanning a certain height space with a 2D laser, but the environment outside the scanning plane is unknown, so to say the perception is very weak.”

Three big problems in the mobile robot industry

Over the past few years, as technology has continued to iterate, the use of mobile robots has broadened from the storage industry of e commerce logistics to manufacturing industries such as LCD panel manufacturing and photovoltaic panel manufacturing.

Zheng Chao analyzed that with the increase of application scenarios, the mobile robot industry has been further developed, and has started to move from track to trackless, from low flexibility to high flexibility, and from safety to safer, but so far, there are still three industry problems, namely, reliable non-marking location in complex environment, safe obstacle avoidance in complex environment and high-precision non-marking docking.

On the problem of unlabeled localization in complex environment, Zheng Chao tells the difficult problem of mobile robot in two cases.

In a typical warehouse, all the pallets and goods around the warehouse can be changed at any time, and there is no fixed reference object. At present, the SLAM scheme, which is widely used in mobile robots, is based on the principle of laser ranging, scanning the outline environment of a production shop or warehouse for precise positioning, but the frequent in and out of the warehouse and the constant change of the position of the Pallet mean that the outline environment of laser scanning is constantly changing, for a laser-guided mobile robot, reliable positioning in a changing environment is difficult.

Another typical scene is a large open shop with steel columns and large distance between columns. In this scene, the point clouds scanned by laser are few, because of the lack of effective positioning reference object, the reliability of its positioning is reduced.

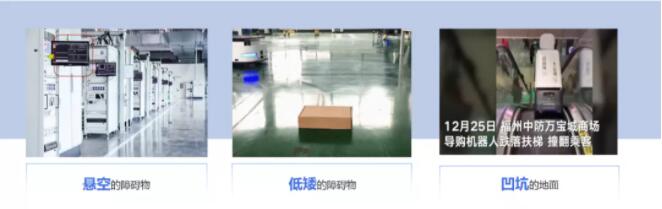

The second challenge is to avoid obstacles safely in complex environments. The screen and operating keyboard outstretched beside the cabinet, the small paper boxes and spare parts left in the driving path, the pit floor and the cliff floor, relative to the robot, workers... These circumstances mobile robots need to take the initiative to judge and avoid. Obstacle avoidance by 2D LIDAR is a routine obstacle avoidance scheme for a trackless mobile robot, but 2D LIDAR can only scan obstacles on one horizontal plane, and obstacles above or below the laser can not be recognized, this brings the hidden danger to the safe driving of the robot.

The third challenge is high-precision docking without identification. With the development of mobile robots, the level of intelligence of AGV has been further strengthened. At the same time, customers have higher expectations of mobile robots. Mobile robots not only need to carry the past point to point, it also needs to replace some of the manual work. Zheng Chao analyzed that this requirement was directly implemented in the application case, that is, the mobile robot not only helped me transfer the raw materials from the warehouse to the production line, but also directly sent the materials to the machine, and did not need manual participation in the whole process, this requires the mobile robot to have higher precision.

Zheng concluded that these problems are related to the lack of perception of mobile robots.

Give mobile robots the eye of wisdom

We’ll cross that bridge when we come to it. Zheng Chao said that in the view of blue core technology, depth vision is the mobile robot to improve the perception of the “Road”, so blue core technology since its inception to depth vision technology as the core, hoping to give the robot a pair of “Intelligent eyes.”.

About how depth vision can be the “Eye”that allows a robot to see the world, zheng said: “80% of human perception is through the eyes to obtain external information, and blue core technology through the self-developed ‘RGBD camera + Ai Algorithm’, let mobile robots through the TOF camera to obtain three-dimensional environment depth image information, combined with Ai Algorithm, can achieve mobile robots highly reliable positioning, obstacle avoidance, docking and other functions.”

Regarding the reliability of the technology, Zheng Chao said that blue core technology not only develops the vision sensor, but also develops the whole machine product with the depth vision as the core, it is the first enterprise in the field of mobile robot to develop MRDVS (deep vision system of mobile robot) and realize mass application. There are a lot of practical cases.

With concrete products and detailed application cases, Zheng Chao shows how depth vision can endow mobile robot eyes.

In the localization of the mobile robot, by installing the vision localization navigation sensor, the mobile robot can carry on the depth survey to the ceiling through the Vision Sensor under the environment of the low heap storehouse, after the depth study realizes the accurate localization. In the five-meter-high warehouse, Blue Core Technology Mobile Robot Vision Repeat Positioning accuracy can be accurate to 5 mm level.

In the application of obstacle avoidance of mobile robot, the mobile robot with Blue Core Technology “Self-developed ToF obstacle avoidance camera + Algorithm”after acquiring the point cloud map of the object, whether it is low or hanging obstacles, the robot can judge the obstacle by the AI algorithm, so it can plan the path and avoid the risk.

Regarding the high-precision docking of mobile robots, Zheng Chao said that the future mobile robots are highly integrated with “Legs”, “Hands”and “Eyes”, which is the inevitable development of mobile robots and the most valuable applications, high-precision docking can continuously broaden the application boundaries of mobile robots, access to more jobs and markets.

At the end of the speech, “Blue Core has a mature team and a complete product Matrix,”says Zheng. In the team size, currently about 200 blue chip technology, OF WHICH R & D accounted for more than 50% . On the product line, has two big product lines, one is the vision sensor product line including the algorithm, another is each series of complete machine product line including the upper level dispatch system software. In the future, bluechip will continue to drive the mobile robot industry with the mission of ‘letting robots see the world, serving the world’.”