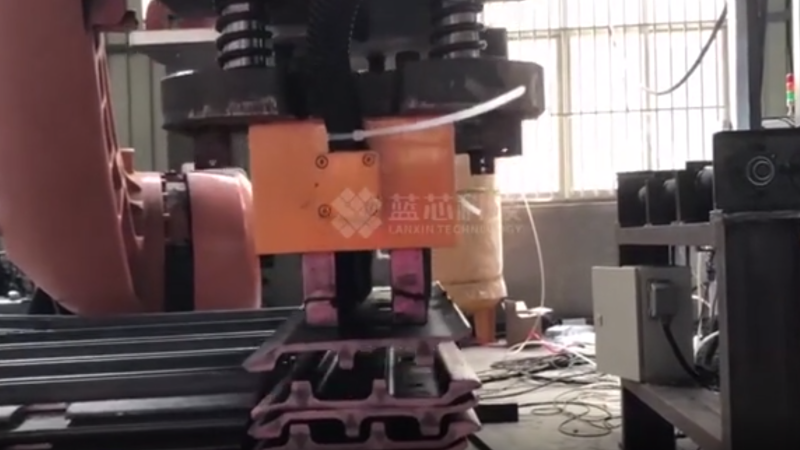

High adaptability

For use in harsh environments.

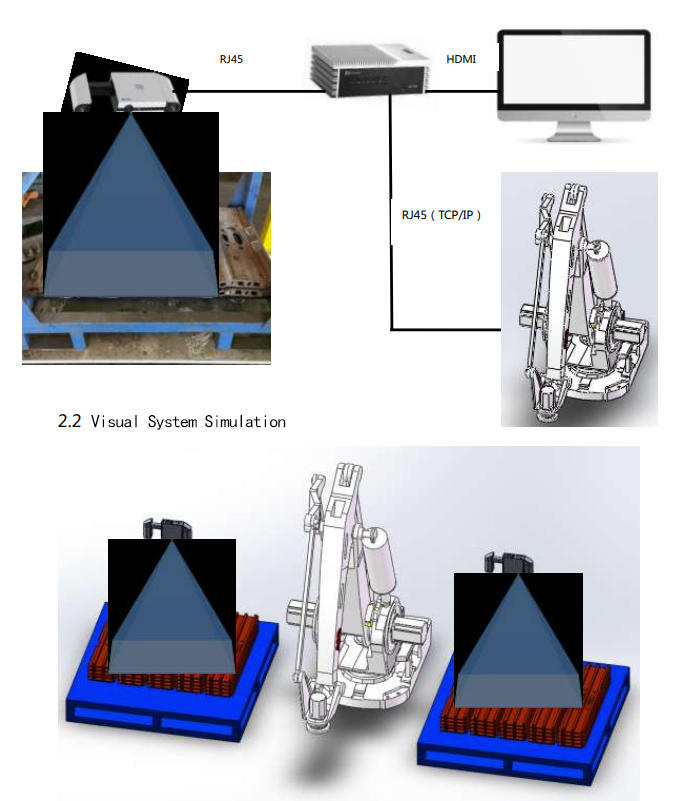

Optimal positioning

Location Optimal Single 3D grab location.

Rapid identification

No need for CAD files, through deep learning to enable the machine to quickly identify objects.

High precision

Maximum point cloud accuracy 0.02 mm.

Fast

Acquisition time < 0.4 S.