Unmarked visual navigation

Multi-sensors are fused to avoid obstacles and ensure the security in the warehouse and other scenarios.

Matching requirement

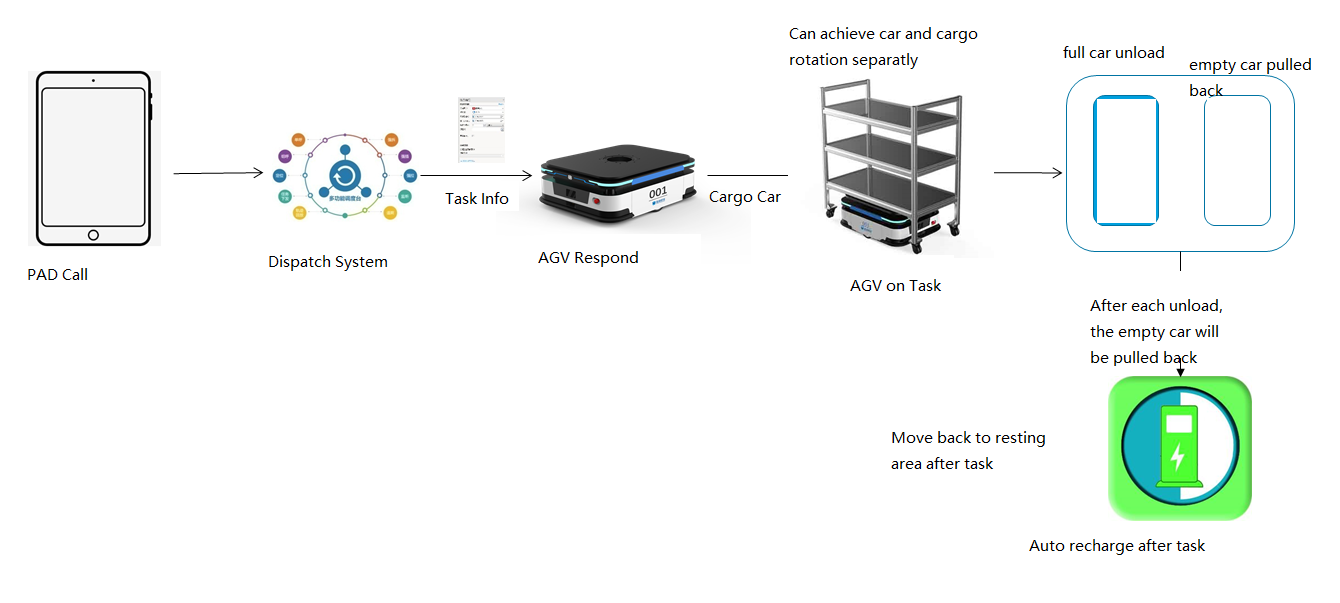

Supporting artificial voice call material system.

Easy to use

USER-FRIENDLY UI settings, easy to learn, faster to start, easy to deploy construction.

Opening up

Seamless docking of MES/WMS/ERP information platform and third-party robots or RCS.

High efficiency

Based on intelligent algorithm, large-scale multi-robot scheduling is realized, and the cooperative work is efficient.